Ulwazi

-

Sombulula iingxaki ezibangelwa kukusetyenziswa kwezithuthi zombane ngokutshintsha iibhetri zesithuthi sombane

Inkokeli: I-US National Renewable Energy Laboratory (NREL) ibika ukuba imoto yepetroli ixabisa i-$ 0.30 ngekhilomitha, ngelixa isithuthi sombane esinoluhlu lweekhilomitha ezingama-300 sixabisa i-$ 0.47 ngekhilomitha, njengoko kuboniswe kwitheyibhile engezantsi.Oku kubandakanya iindleko zokuqala zesithuthi, iindleko zepetroli, iindleko zombane kunye ...Funda ngokugqithisileyo -

Thetha malunga neembono zakho kuyilo lwemowudi ene-pedal enye

Imowudi ye-One Padel yezithuthi zombane ibisoloko ingumxholo oshushu.Yintoni imfuneko yolu seto?Ngaba olu phawu lunokuvalwa ngokulula, lubangele ingozi?Ukuba akuyongxaki kwindlela eyilwe ngayo imoto, ngaba zonke iingozi ziluxanduva lomnini-moto ngokwakhe?Namhlanje ndifuna...Funda ngokugqithisileyo -

Uhlalutyo olunzulu lwemarike ye-EV yokutshaja yaseTshayina ngoNovemba

Kungekudala, mna noYanyan senze uluhlu lweengxelo ezinzulu zenyanga (ezicetywayo ukuba zikhutshwe ngoNovemba, ngokukodwa ukushwankathela ulwazi ngo-Oktobha) , ngokukodwa ukugubungela iinxalenye ezine: ● Izibonelelo zokutshaja Qaphela imeko yeendawo zokuhlawula eChina. , uthungelwano oluzakhele lona...Funda ngokugqithisileyo -

Ukuqala ngesithuthi samandla esitsha, zeziphi iinguqu eziziswe kubomi bethu?

Ngokuthengiswa okushushu kunye nokuthandwa kweenqwelo zombane ezintsha zamandla, izigebenga zangaphambili zezithuthi zamafutha nazo ziye zabhengeza ukuba ziluyekile uphando kunye nophuhliso lweenjini zamafutha, kwaye ezinye iinkampani zade zabhengeza ngokuthe ngqo ukuba ziyakumisa ukuveliswa kweenjini zamafutha kwaye zingene ngokupheleleyo kumbane. ..Funda ngokugqithisileyo -

Yintoni isithuthi sombane soluhlu olwandisiweyo?Izinto eziluncedo kunye nezingeloncedo zoluhlu olwandisiweyo lwezithuthi zamandla amatsha

Intshayelelo: Iinqwelo zombane zomgama owandisiweyo zibhekisa kuhlobo lwesithuthi esiqhutywa yimoto emva koko sihlawuliswe yi-injini (uluhlu olude) kwibhetri.Uluhlu lwesithuthi sombane esandisiweyo sisekelwe ekongezwa kwenjini yepetroli kwisithuthi esicocekileyo sombane.Eyona functi...Funda ngokugqithisileyo -

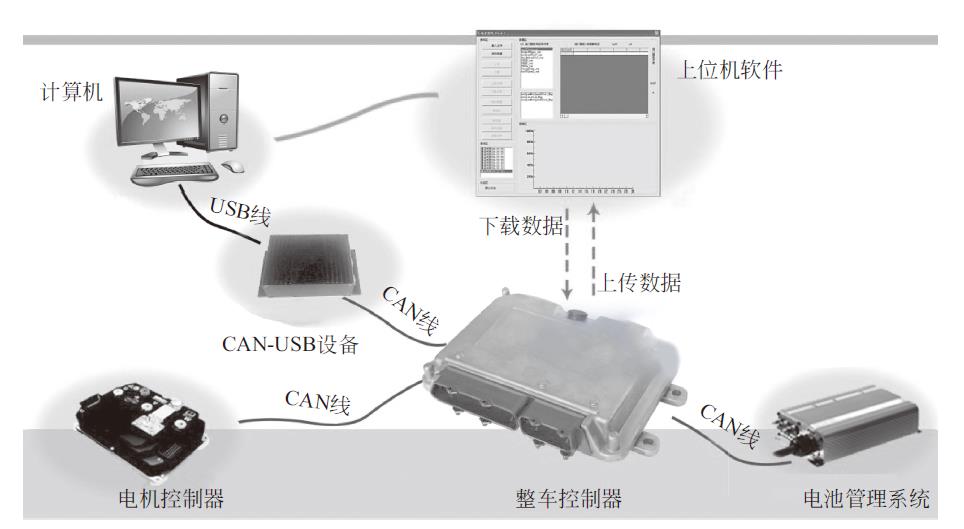

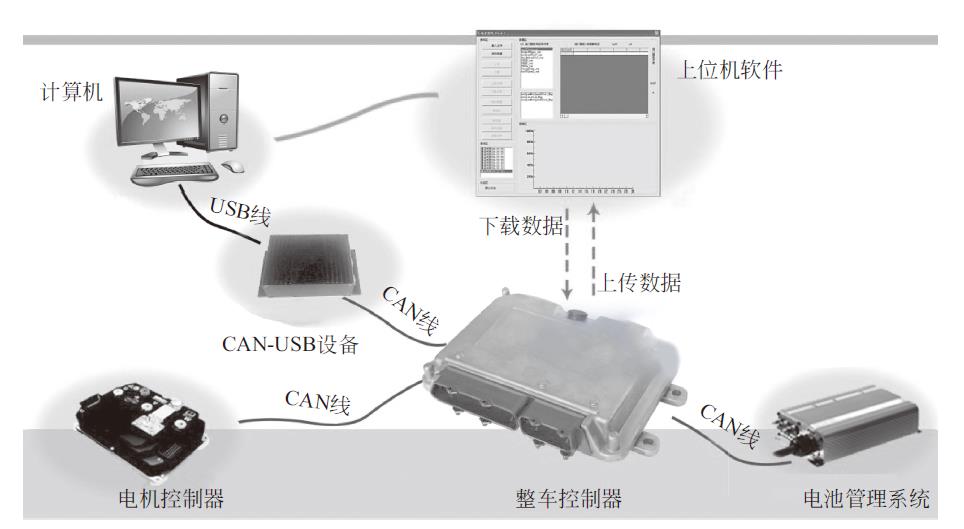

Umgaqo kunye nohlalutyo lomsebenzi womlawuli wesithuthi sombane ococekileyo

Intshayelelo: Umlawuli wesithuthi liziko lolawulo lokuqhuba okuqhelekileyo kwesithuthi sombane, eyona nxalenye ingundoqo yenkqubo yokulawula isithuthi, kunye nomsebenzi ophambili wokuqhuba okuqhelekileyo, ukubuyiswa kokuvuselela amandla okuqhobosha, ukusetyenzwa kwempazamo kunye nokubeka iliso kwimeko yesithuthi. ..Funda ngokugqithisileyo -

Ukwabelana ngomthombo ovulekileyo!I-Hongguang MINIEV yokuthengiswa kwe-decryption: imigangatho eyi-9 ephambili ichaza umda omtsha we-scooter

Kuthathe iminyaka emihlanu kuphela ukuba iWuling New Energy ibe lolona hlobo lwamandla akhawulezayo kwihlabathi ukufikelela kwintengiso yesigidi esi-1.Siyintoni isizathu?UWuling unike impendulo namhlanje.Nge-3 kaNovemba, iWuling New Energy ikhuphe "imigangatho elithoba" ye-Hongguang MINIEV esekwe kwiGSEV yegcisa...Funda ngokugqithisileyo -

I-automation ye-automation ikwimfuno enamandla.Iinkampani ezidweliswe kwiirobhothi zemizi-mveliso ziyahlangana ukuze zivune iiodolo

Intshayelelo: Ukususela ekuqaleni kwalo nyaka, ishishini elitsha leemoto zamandla liye lakhawulezisa ukwandiswa kwemveliso, kwaye ukunyuka nokwehla kweshishini kuye kwaxhomekeka ngakumbi kwimveliso ezenzekelayo kunye nemveliso.Ngokutsho kwabangaphakathi kwishishini, imfuno yentengiso ...Funda ngokugqithisileyo -

Inkcazo ecacileyo yomgaqo wokusebenza, ukuhlelwa kunye neempawu zeenjini ze-stepper

Intshayelelo: I-Stepper motor yimoto yokungenisa.Umgaqo wayo wokusebenza kukusebenzisa iisekethe ze-elektroniki ukwenza iisekethe ze-DC ukubonelela amandla ekwabelwaneni kwexesha, ulawulo olulandelelanayo lwezigaba ezininzi lwangoku, kwaye usebenzise le yangoku ukunika amandla i-motor stepper, ukuze i-motor stepper isebenze ngokwesiqhelo....Funda ngokugqithisileyo -

Ukukhawulezisa ukufezekiswa kwezithuthi zamandla amatsha ezinkulu kwaye zomelele

Intshayelelo: Ngexesha loshishino lweemoto, njengesona sixhobo siphambili sokuhamba ngeselula kubantu, iimoto zihlobene ngokusondeleyo kwimveliso yethu yemihla ngemihla kunye nobomi.Nangona kunjalo, iimoto zamandla emveli eziqhutywa yipetroli kunye nedizili zibangele ungcoliseko olukhulu kwaye zenze isoyikiso kwi ...Funda ngokugqithisileyo -

Kuthetha ukuthini umlinganiselo wesantya?

Umlinganiselo wesantya yintsingiselo yomlinganiselo wothumelo lwemoto.IsiNgesi somlinganiselo wesantya ngumlinganiselo wokuhambisa i-tnotor, ebhekisela kumlinganiselo wesantya seendlela ezimbini zokuhambisa ngaphambi nangemva kokudluliselwa kwinkqubo yokuhanjiswa kwemoto.I-tr...Funda ngokugqithisileyo -

Yintoni umahluko phakathi kwemoto eguquguqukayo kunye nemoto eqhelekileyo?

Intshayelelo: Umahluko phakathi kweenjini eziguquguqukayo kunye neenjini eziqhelekileyo ubonakaliswa ikakhulu kule miba mibini ilandelayo: Okokuqala, iinjini eziqhelekileyo zinokusebenza kuphela kufutshane nezandi zombane ixesha elide, ngelixa ii-motor frequency frequency zinokuba phezulu kakhulu okanye zibe sezantsi kunoko. apho...Funda ngokugqithisileyo